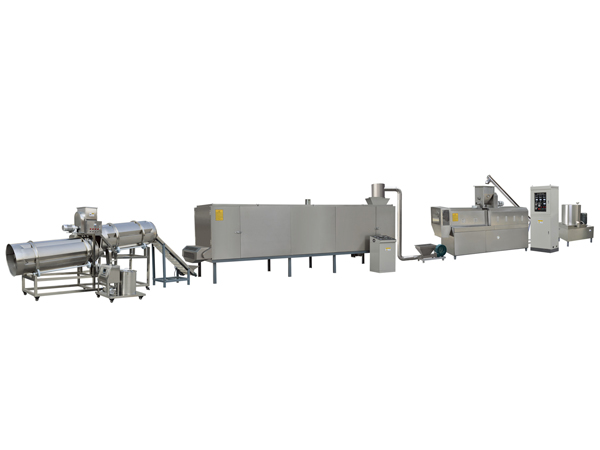

Pet food production line

Large pet food and pet snack puffing equipment:

Large pet food and pet snack puffing equipment are available for customers to choose from a variety of production models ranging from 150-1000kg/h. The equipment operates stably. Strong operability. Other high-grade feeds can be produced by changing the production process and related accessories. Provide customers with large production benefits. Pet food production line adopts advanced twin-screw extrusion technology. The dog food production line produced by dongxuya Machinery Equipment Co., Ltd. can be completed at one time from raw material crushing to finished product packaging. Advanced technology and stable operation. Meet the production needs of different customer groups in the current market.

Process flow of large pet food production line:

Raw material crushing - mixing - expansion - drying - spraying - packaging

Supporting equipment for large pet food pet snack expansion equipment (different raw materials and auxiliary equipment):

1. crusher: to crush various grain raw materials. Meet the requirements for the production of pet food raw materials

2. meat and bone separator: fresh meat and bone separation

3. minced meat beater: beat the fresh meat to a fineness of more than 200 mesh. Mix evenly into the cereal ingredients

4. bone crusher: This equipment will be used if you process bone powder yourself

5. powder mixer: mix various raw materials evenly. The powder mixer selected according to different output can also be changed to a vertical mixer. Meet the production demand of large output

6. screw conveyor: save labor intensity. Realize automatic feeding

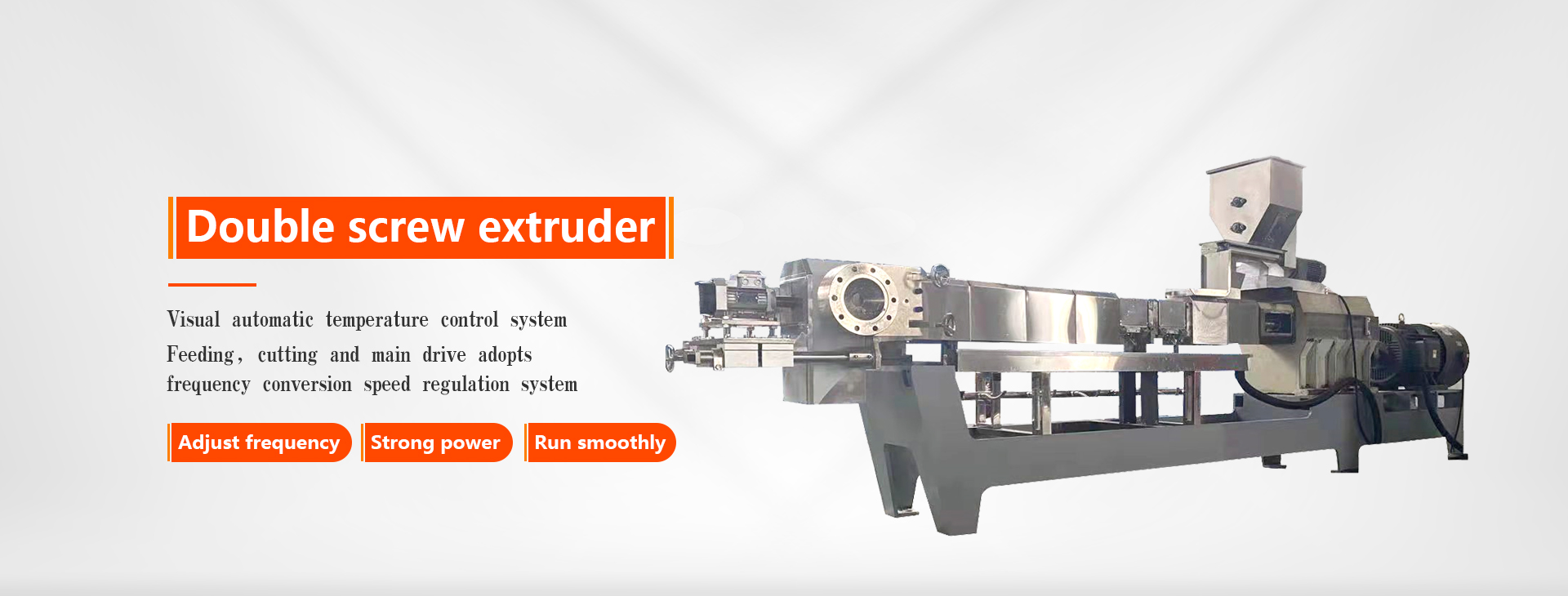

7. twin screw extruder: the dog food produced by this machine is of excellent quality. The nutrition content of dog food produced by single screw was higher than that of dog food produced by single screw, and the proportion of fresh meat content increased by 40%. Equipped with single twin screw modulator. Increase production. Substantial improvement of product quality

8. air blower: conveying products

9. drying oven: the drying oven can adopt multi-layer circulating oven according to different fuels. Steam heated. Fuel oil type, gas type, electric heating type, hot air circulation type and other drying methods

10. flavoring line: including elevator, flavoring machine, single (double) roller and fuel injector. Apply oil on the surface of the dried particles and add various vitamins. The spraying technology adopts advanced technology.

11. Cooler: cooling the product is conducive to product packaging

12. Silo: store products for a period of time

13. packer: used for product packaging

Large pet food and pet snack puffing equipment are available for customers to choose from a variety of production models ranging from 150-1000kg/h. The equipment operates stably. Strong operability. Other high-grade feeds can be produced by changing the production process and related accessories. Provide customers with large production benefits. Pet food production line adopts advanced twin-screw extrusion technology. The dog food production line produced by dongxuya Machinery Equipment Co., Ltd. can be completed at one time from raw material crushing to finished product packaging. Advanced technology and stable operation. Meet the production needs of different customer groups in the current market.

Process flow of large pet food production line:

Raw material crushing - mixing - expansion - drying - spraying - packaging

Supporting equipment for large pet food pet snack expansion equipment (different raw materials and auxiliary equipment):

1. crusher: to crush various grain raw materials. Meet the requirements for the production of pet food raw materials

2. meat and bone separator: fresh meat and bone separation

3. minced meat beater: beat the fresh meat to a fineness of more than 200 mesh. Mix evenly into the cereal ingredients

4. bone crusher: This equipment will be used if you process bone powder yourself

5. powder mixer: mix various raw materials evenly. The powder mixer selected according to different output can also be changed to a vertical mixer. Meet the production demand of large output

6. screw conveyor: save labor intensity. Realize automatic feeding

7. twin screw extruder: the dog food produced by this machine is of excellent quality. The nutrition content of dog food produced by single screw was higher than that of dog food produced by single screw, and the proportion of fresh meat content increased by 40%. Equipped with single twin screw modulator. Increase production. Substantial improvement of product quality

8. air blower: conveying products

9. drying oven: the drying oven can adopt multi-layer circulating oven according to different fuels. Steam heated. Fuel oil type, gas type, electric heating type, hot air circulation type and other drying methods

10. flavoring line: including elevator, flavoring machine, single (double) roller and fuel injector. Apply oil on the surface of the dried particles and add various vitamins. The spraying technology adopts advanced technology.

11. Cooler: cooling the product is conducive to product packaging

12. Silo: store products for a period of time

13. packer: used for product packaging

Pet food production line sample display

Product parameters

| Host model | Install power | Actual power |

Output |

Size |

| DXY65 | 74KW | 52KW | 100-150kg/h | 17000*1300*2200mm |

| DXY70 | 105KW | 75KW | 200-260kg/h | 20000*1500*2200mm |

| DXY85 | 205KW | 150KW | 400-500kg/h | 30000*1500*2600mm |

Production line display Equipment details display

Pet food production line

- Highly automatic

- Low cost

- reduce space

- stir well

- Good stability

- High output

- Previous:Pet food production line

- Next:Pet food production line

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan

Copyright ©2022 SHANDONG DONGXUYA MACHINERY CO., LTD Record No:鲁ICP#16042769-2 Technical Support:51La