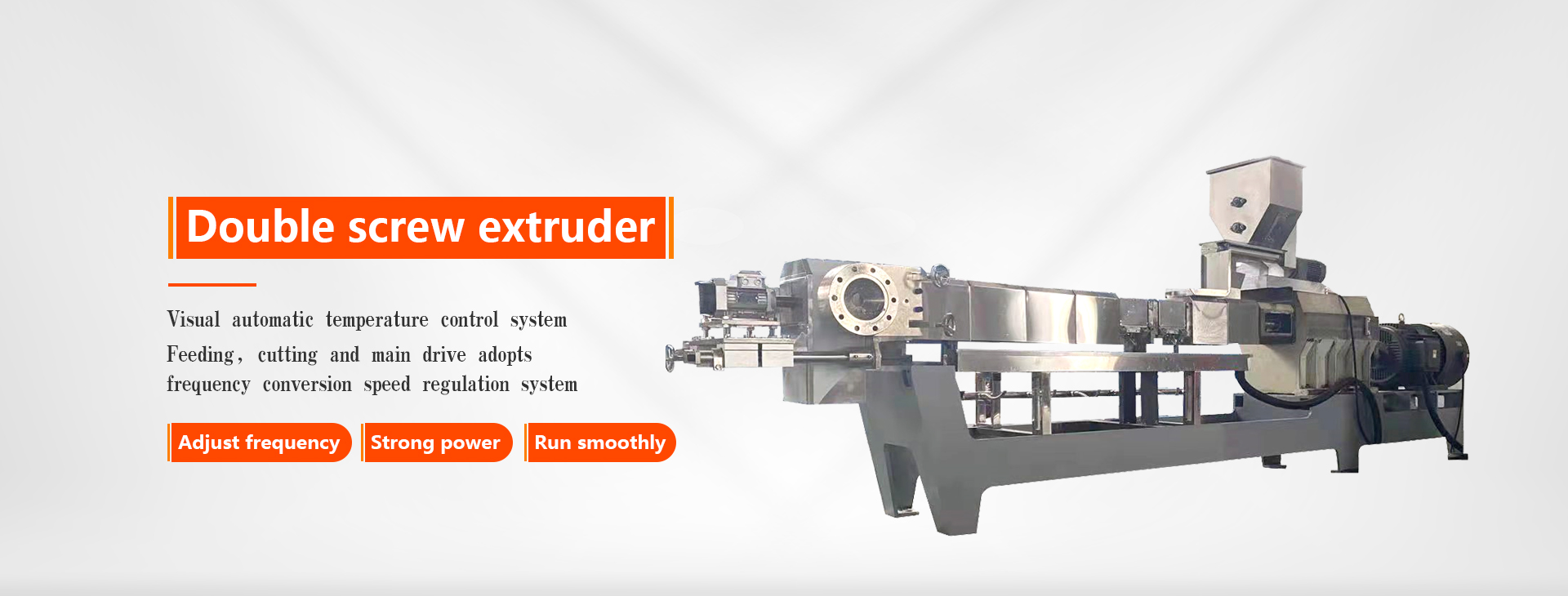

75Extruder Machine

1.Function of 75 type extruder:

The application field of twin-screw extruder covers the deep processing of agricultural products, such as breakfast instant porridge, nutritional rice, instant rice, breakfast cereal food, leisure puffed food, silk drawing protein, modified starch, pet food, aquatic feed and other processing fields.

Twin screw extruder is composed of feeding system, extrusion system, rotary cutting system, heating system, cooling system, transmission system and control system. The machine is suitable for a wide range of raw materials, various production products, variable frequency speed regulation, high degree of automation, stable operation and long service life.

The full-function twin-screw expansion host has better equipment performance. The gear box is solid and durable. The screw uses a combination of building blocks, which is applicable to a wider range of products. The barrel uses an embedded alloy sleeve structure, which is more wear-resistant and durable.

2、Performance parameters of 75 type extruder:

Motor performance: variable frequency speed regulation of main motor, feeding motor and rotary cutting motor.

Frame: carbon steel frame and stainless steel cover are optional.

Gear box: the box bearing is NSK, the gear is high-strength alloy nitriding steel, the transmission ratio is 1:2.9, and the anti vibration oil gauge is used for the oil gauge.

Gearbox cooling: forced external cooling system of lubricating oil in the gearbox and bucket filtration provide a high working environment for the gearbox.

Screw: the screw is made of alloy steel, built-up screw, screw diameter: 57mm, length diameter ratio: 1:25.5, effective length of screw thread: 1453.5mm.

Barrel: the barrel is square or round, with alloy steel lining embedded inside and 45 material outside. The barrel is cooled by the return channel

Heating control: resistance heating or steam heating structure

Cooling control: independent control in each area, electric heating automatic control, steam heating manual control

Rotary cutting: the open door push-pull rotary cutting device is easy to disassemble. All machined parts use electroplating standards. Beautiful appearance, material of rotary cutting cover is 201

Feeding machine: forced mixing and feeding, feeding screw quantitative conveying, uniform and stable feeding.

Control cabinet: PLC touch screen control or button control

| Installed Power | Main Motor Power | Capacity | Overall Dimension |

|

75kw |

55kw |

300-500kg/h |

3.5×1.0×1.8m |

- Previous:It's already the first one

- Next:Double Octagon Flavoring Line

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan