- Company News

- Industry News

- Question

Question

Selection of microwave drying machine

Materials of microwave machine: materials are one of the main factors affecting the price of equipment. Therefore, when purchasing microwave equipment, customers must make clear the materials used in the equipment and make the best use of everything.

Materials of microwave machine: materials are one of the main factors affecting the price of equipment. Therefore, when purchasing microwave equipment, customers must make clear the materials used in the equipment and make the best use of everything.

The service life of a successfully designed microwave equipment is very long. Its mechanical part usually rarely breaks down due to its slow speed and low load. If sufficient materials are used in the cavity, there is almost no chance of problems. The rest is the electrical part. The magnetron (microwave generator) in the electrical part is an electric vacuum device with a certain service life. Under normal use, the service life is generally 4000-5000 hours. If the control part is designed in place, it is also normal that the service life exceeds 8000 hours. The hot air of the microwave drying equipment enters the annular gap at the bottom of the drying chamber in a tangent direction from the inlet pipe and rises spirally. At the same time, the materials are quantitatively added into the tower by the feeder and are fully heat exchanged with the hot air. The larger and wetter materials are mechanically broken under the action of the agitator. The materials with lower moisture content and smaller particle size rise with the rotating air flow and are transported to the separator for gas-solid separation. The finished products are collected and packaged, The tail gas is discharged after being treated by the dust removal device.

Microwave fixing and drying means that the microwave generator radiates the microwave to the fixing and drying materials and penetrates them into the interior, inducing the water and other polar molecules of the materials to rotate synchronously, rotating billions of times per second. As far as the drying rate is concerned, the materials are highly dispersed in hot air during convective drying. The critical moisture content is low and the drying speed is fast. In addition, the same convective drying, the critical moisture content is different with different drying methods, so the drying rate is also different. As a result of such high-speed rotation, the material will generate friction heat instantaneously, causing the surface and interior of the material to rise at the same time, and the internal temperature is higher than the surface temperature of the material, making the enzyme inactive and part of the water molecules evaporate at the same time, so as to achieve the purpose of killing and drying. The characteristics of this method are that the heating time is short, the internal and external temperatures are the same, and the heat transfer direction from the inside to the outside is also the same as the wet transfer direction. Different from the conventional heating method, it takes a certain time to heat the heat from the outside to the inside of the material. There is a problem that the internal and external temperature difference is opposite to the wet and heat transfer direction.

Microwave can penetrate into the material for heating and does not need high-temperature thermal medium. When applied to tea processing, it fundamentally changes the conventional heating method that relies on high-temperature medium and heat conduction. At the same time, due to the non thermal effect of microwave electromagnetic field in the process of green killing and drying, the processing time is greatly shortened, showing the unique advantages of microwave. Different drying methods have different energy consumption indicators. Generally, the thermal efficiency of conduction drying can reach 100% in theory, and that of convection drying can only be about 70%.

- Previous:Already the first article

- Next:How to choose microwave drying machine?

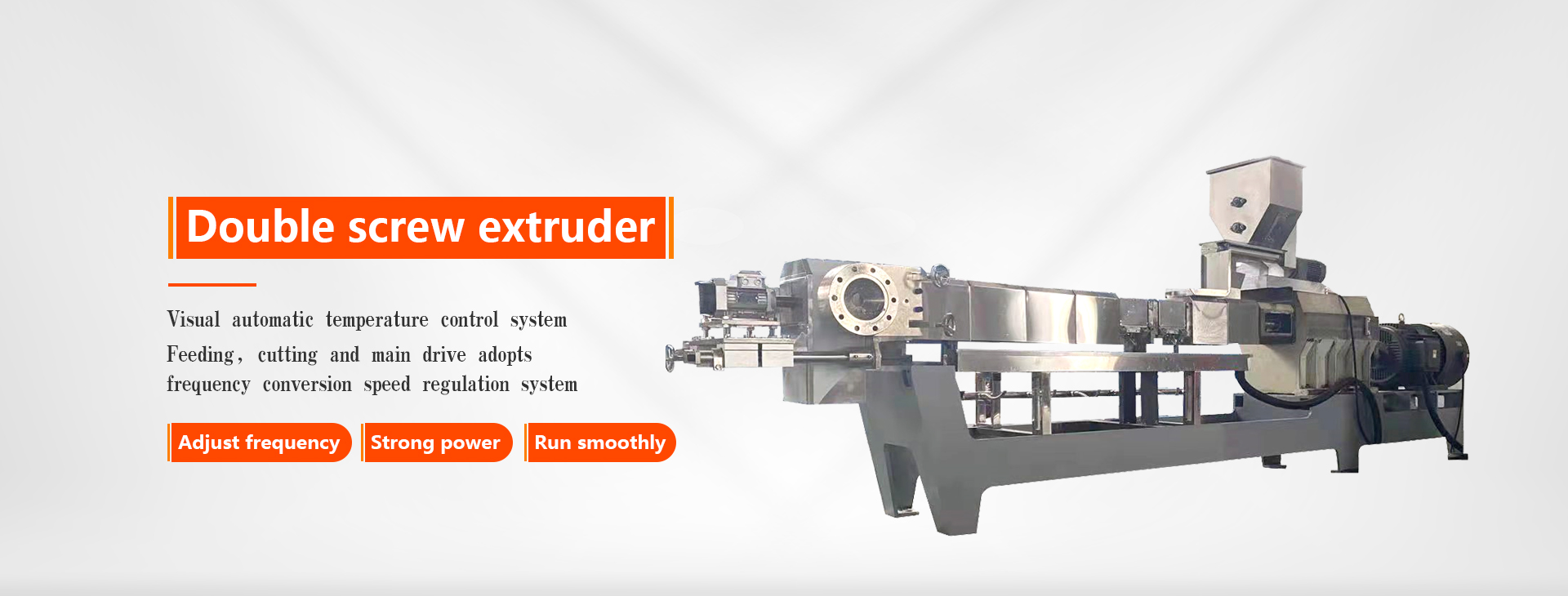

It is committed to upgrading the overall technical level of microwave drying equipment, single extruder and extruder production line

With advanced technology, strict management and perfect service, the company has been highly praised by users at home and abroad, and has achieved very impressive performance, occupying a place in the expansion industry

-

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305

Contact: Trade Dep.:15562590818 Trade Dep.: 15588827305 -

E-Mail:

E-Mail:

info@dongxuya.com -

Company ADD:

Company ADD:

No.14,DM Industrial Park,Jinan City,China

Scan